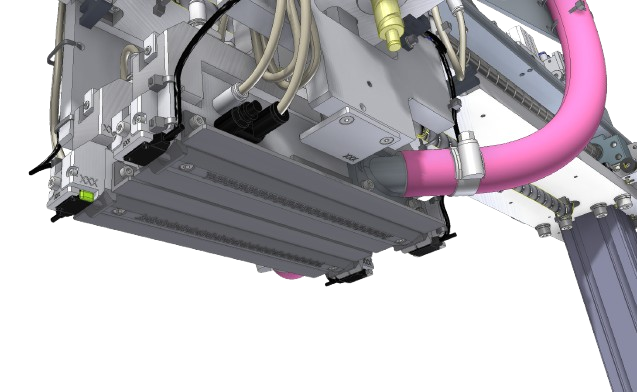

Universal Gang Pick (UGP)

Advanced vacuum-based object transfer mechanism for semiconductor inspection

Key Features

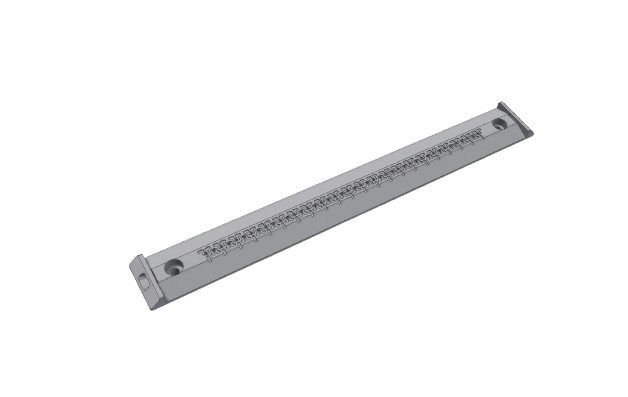

Matrix Flexibility

Handles any row or column arrangement regardless of spacing or device count

Single Operation Transfer

Transfers entire rows or columns at one go using vacuum technology

Zero Configuration Change

Adapts to different pocket matrices without mechanical adjustments

Integrated Inspection

Seamlessly transfers devices to vision inspection systems

Cost-Effective Operation

Eliminates tooling change costs and reduces setup time